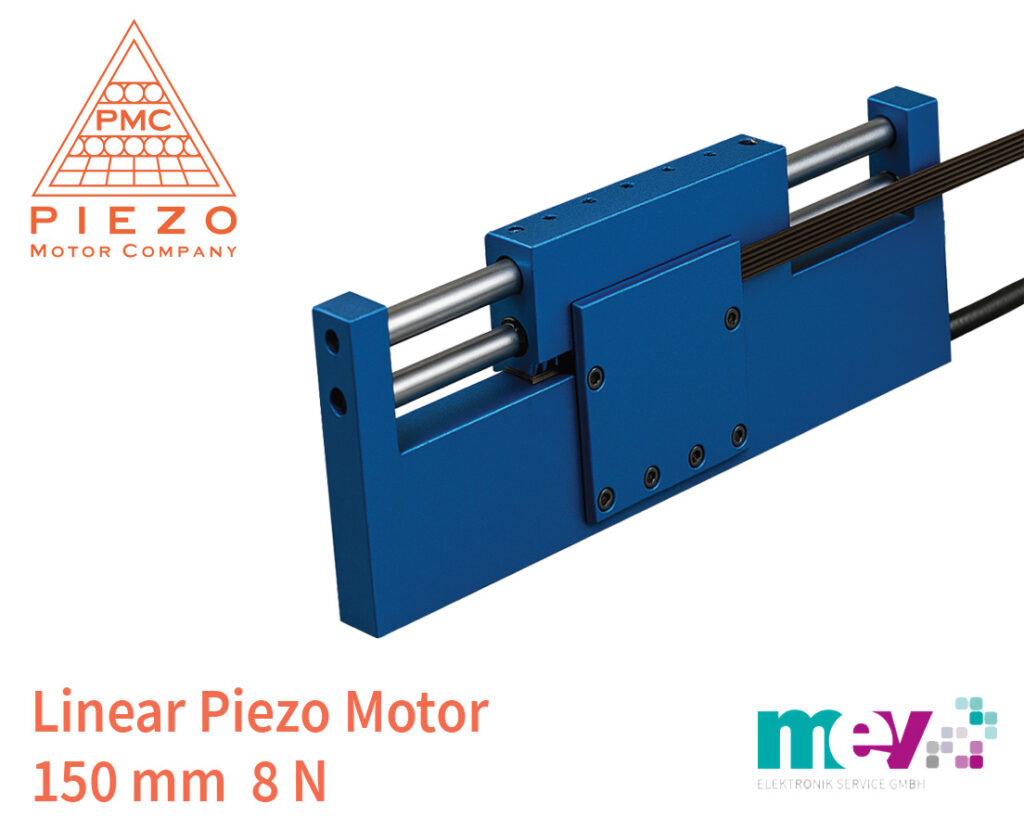

LRMO-150 Linear Piezo Motor – Precision Motion Redefined.

MEV introduces the LRMO-150 Linear Piezo Motor from Piezo Motor Company (PMC). This innovative actuator represents a significant advancement in compact linear motion technology, combining micrometer precision, fast response, and energy-efficient operation for demanding industrial and scientific applications.

Next-Generation Linear Motion Performance

The LRMO-150 is part of PMC’s newest series of piezoelectric linear motors, designed to deliver unmatched motion control performance.

Featuring an extended stroke of 150 mm (with custom lengths available), the LRMO-150 offers an open-loop step size of just 0.04 µm, enabling 25,000 precise steps per millimeter of linear travel.

In closed-loop operation, with an optional factory-fitted magnetic encoder, the motor achieves a controlled step size of 2.6 µm and uni-directional repeatability of the same order.

Key technical characteristics

- Travel Range: 150 mm (customizable)

- Max Speed: up to 200 mm/s

- Response Time: approx. 30 µs

- Force Output: ≥ 8 N (push/pull)

- Resolution: 0.04 µm open-loop / 2.6 µm closed-loop

- Operating Temperature: -20 to +80 °C

- Motor Weight: 500 g

With a high dynamic speed range and zero power consumption in holding mode, the LRMO-150 provides a superior balance of speed, precision, and energy efficiency. Its electromagnetic immunity and non-magnetic construction make it ideal for use in MRI environments, optical instruments, metrology, and precision robotics.

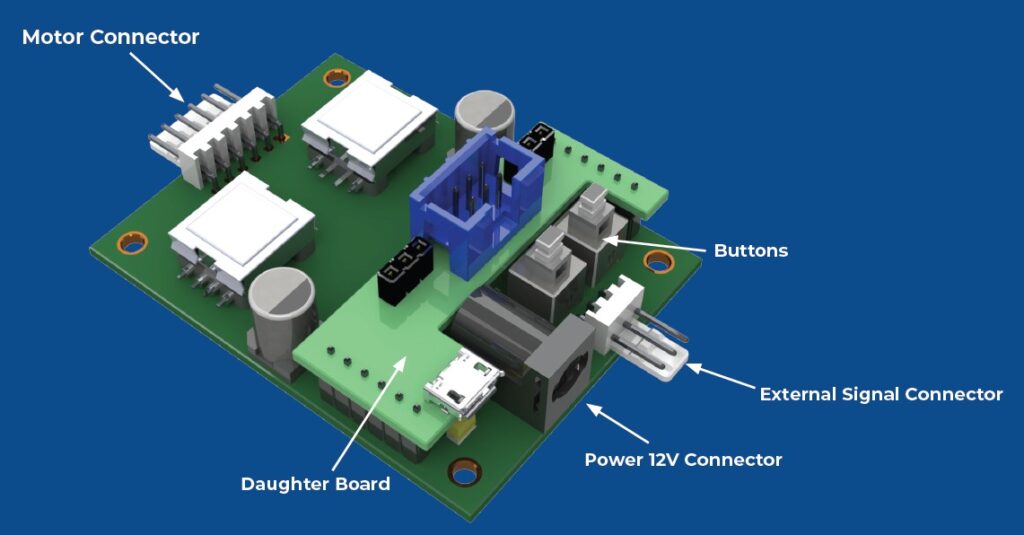

Advanced Control Architecture with the Electronic PCB Driver

Each LRMO-150 motor is paired with a dedicated Electronic PCB Driver (model ROLR-150-PCB or ROLR-150-CL-PCB for encoder versions).

This compact 12 V driver board converts user input commands into the precise electrical waveforms needed to excite the piezo resonator, enabling smooth motion in both stepping and continuous modes.

Control options

- Open-Loop Operation via PWM control signals for external controllers

- Closed-Loop Operation with serial interfacing and feedback using the PMC encoder

- Software Integration: Compatible with PMC’s Motor Control Software and Python API for easy integration into embedded systems

- Evaluation Kits available, including motor, driver PCB, cables, and power supply

The driver’s pre-programmed motion algorithms and configurable frequency and amplitude profiles simplify system design and reduce time-to-market for OEM customers.

Advantages for MEV and Its Customers

The collaboration between MEV Elektronik and Piezo Motor Company combines leading-edge technology with local engineering support and European market expertise. For MEV customers, the LRMO-150 offers:

- Access to ultra-precise linear motion with nanometer-level resolution

- Simple system integration using the compact 12 V Electronic PCB Driver

- Superior energy efficiency, consuming only 0.5 W at 1 mm/s and zero power in hold position

- Silent, vibration-free operation ideal for medical, laboratory, and optical systems

- EMI and RF immunity for use in sensitive environments

“The LRMO-150 perfectly embodies the evolution of modern motion control — precision, speed, and intelligence in one compact package,” said Guido Gandolfo, Product Line Manager at MEV Elektronik. “With PMC’s advanced driver technology and piezo design expertise, we can now offer our customers a solution that outperforms traditional stepper or servo mechanisms in every aspect.”

Availability & Outlook

The LRMO-150 is now available to order from MEV. Technical information, application data, and samples can be requested directly from the sales department or via the website.

The new LRMO-150 will be presented together with the existing portfolio of linear and rotary piezo motors at SPS show in Nuremberg (25 NOV to 27 NOV 2025) at the MEV booth 174 in hall 4. Specialists from the manufacturer PMC will be present. You are welcome to book an appointment in advance.

About Piezo Motor Company (PMC)

Founded in 2024 and headquartered in Boca Raton, Florida (USA), Piezo Motor Company LLC is dedicated to advancing the capabilities of piezoelectric motion systems.

PMC’s portfolio includes linear and rotary piezo motors, drivers, and custom actuator solutions designed for medical devices, aerospace, robotics, and precision instrumentation.

With a strong focus on research and innovation, PMC combines deep material science knowledge with state-of-the-art control electronics to deliver reliable, compact, and high-performance motion components.

Downloads & Links

LRMO-150 product page

LRMO-150 Technical Brochure (pdf)

Contact

If you would like to know more about LRMO-150, please contact:

Guido Gandolfo

Product Line Manager

Motion Control

+49 5424 2340-57

ggandolfo@mev-elektronik.com