World innovation: energy-efficient, space-saving, cost-cutting

Smart solenoid driver from ADI Trinamic with numerous innovative diagnostic options offers sensor-like functions and simplifies the development of cost-effective miniature actuators.

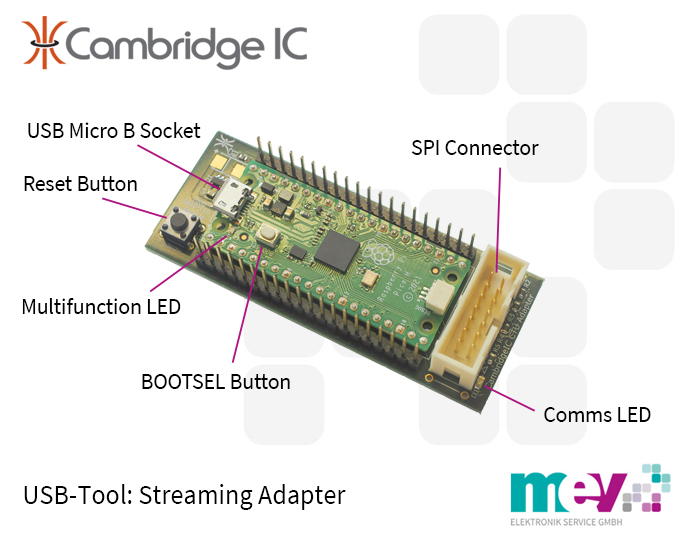

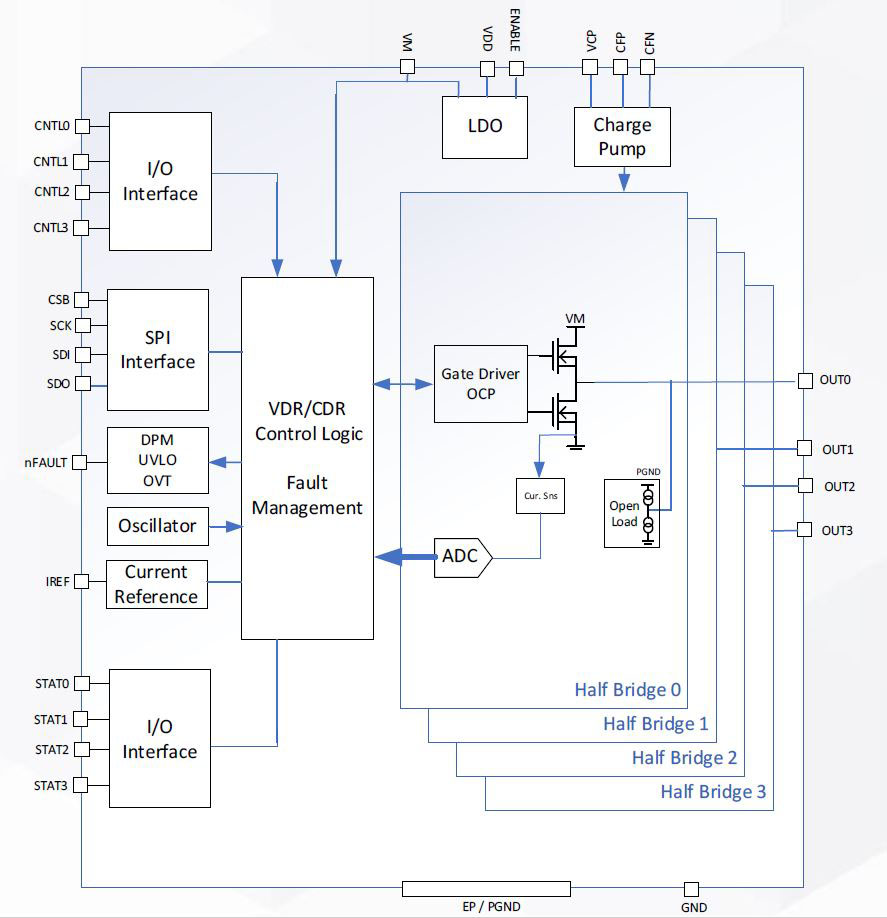

ADI Trinamic’s fully integrated MAX22216 simplifies design with numerous new features. It is primarily intended to drive inductive loads such as on-off solenoid valves, DC motors, proportional valves, bi-stable valves, relays, etc. Each of the 4 half bridges can switch up to 1.7A rms or 3.2A peak at up to 36V. Thanks to the integrated current measurement, no external measuring resistors are necessary.

Advanced diagnostic functions are available to improve system reliability and enable predictive maintenance. These include the world first detection of plunger movement (DPM), inductance measurement, travel time measurement, open-load detection (OL), and real-time current monitoring through a serial SPI Interface. In addition the MAX22216 features a full set of protection circuits, including overcurrent protection (OCP), overtemperature protection (OVT), and undervoltage lockout (UVM). A fault indicator pin is asserted whenever faults are detected.

The MAX22216 half-bridges support two different use cases. In the first case, configuration settings can be entered through a serial peripheral interface (SPI) and can be changed at any time. Alternatively, settings can be stored in one-time programmable (OTP) registers, which are loaded at power-up. This enables stand-alone operations. Registers are user-programmable. The OTP writing procedure must be executed in a factory under well-controlled temperature and voltage conditions.

High-side/low-side single-ended drive operations and bridge-tied load (BTL) configurations are supported. Channel parallelization is also supported. Voltage control (VDR), current control (CDR), and mixed schemes are supported.

In VDR mode, the half-bridge output voltage is controlled. Supply variations are internally compensated.

In CDR mode, the half-bridge output current is controlled. The current is internally sensed and fed back to the controller for accurate closed-loop regulation. Proportional and integral gains can be configured to optimize steady-state errors and dynamic performance.

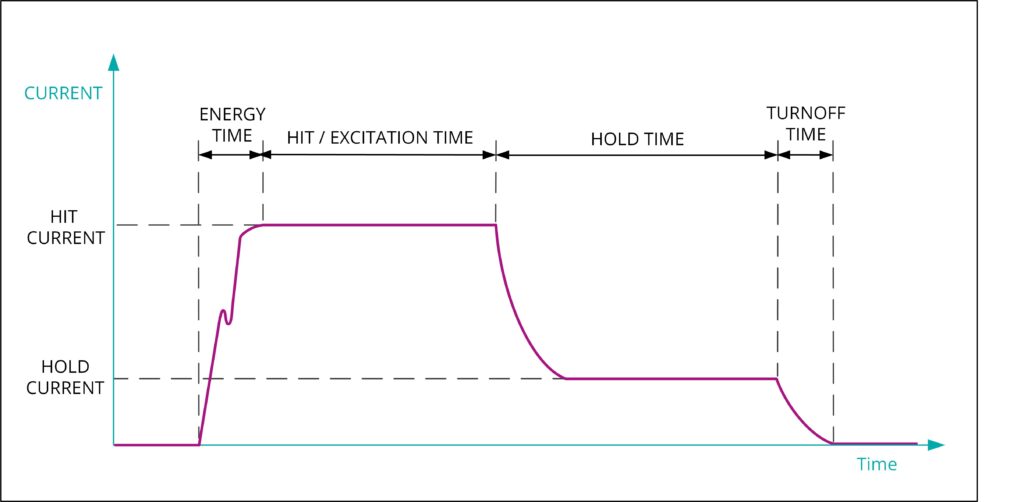

The MAX22216 integrate functions aimed to optimize solenoid and DC motor drive control. These include a two-level sequencer for power saving, drive signal ramp control (RAMP) for noise reduction, a dither function (DITH) to counteract the effects of static friction and hysteresis, a fast demagnetization feature (DC_H2L) to shorten on-off cycles, and a DC-Motor current limiter for limiting inrush and stall currents.

The MAX22216 can operate in ambient temperatures from -40°C to +125°C and is available in the 5x5mm TQFN32 package.

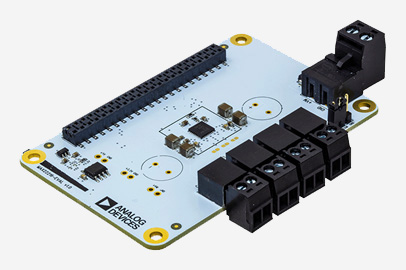

The MAX22216-EVKIT enables easy evaluation of the MAX22216 in combination with ADI Trinamic’s evaluation board system (Landungsbrücke, Eselsbrücke, TMCL-IDE) or as a standalone board.

Downloads & Links

Contact

If you would like to know more about ADI Trinamic solenoid drivers, please contact:

Guido Gandolfo

Product Line Manager

Motion Control

+49 5424 2340-57

ggandolfo@mev-elektronik.com